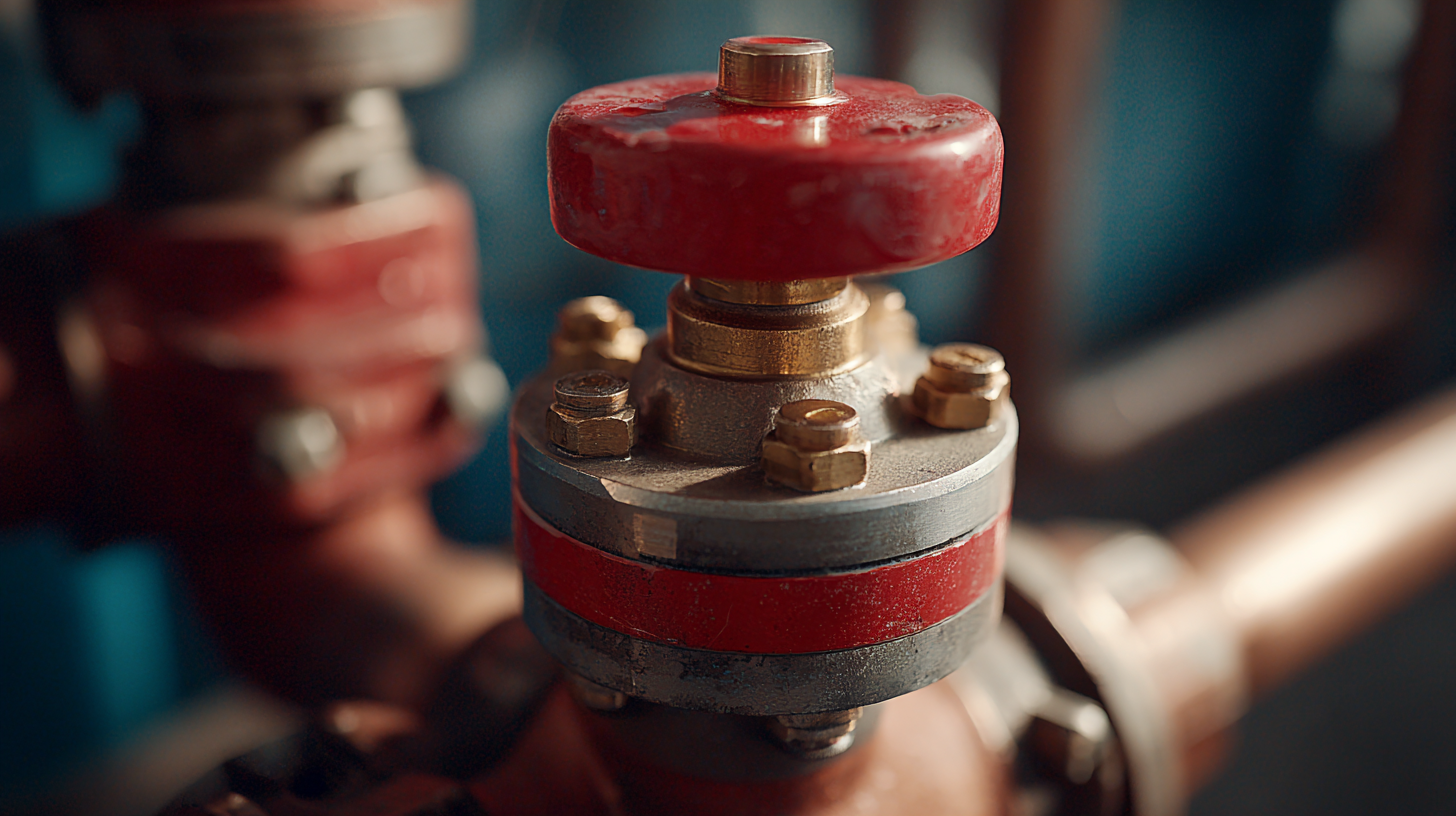

Understanding the Importance of Pressure Relief Valves in Modern Industrial Applications

In the realm of modern industrial applications, the significance of Pressure Relief Valves (PRVs) cannot be overstated. According to a report by MarketsandMarkets, the global pressure relief valve market is projected to reach USD 5.5 billion by 2025, growing at a CAGR of 4.5%. This growth underscores the increasing recognition of PRVs in ensuring operational safety and compliance with stringent regulations. These essential components not only prevent catastrophic equipment failures by relieving excess pressure but also enhance system efficiency and longevity. In sectors such as oil and gas, chemical processing, and power generation, the effectiveness of pressure management is crucial, with safety incidents costing industries millions annually. Understanding the function and maintenance of PRVs is therefore critical for engineers and operators seeking to optimize their operations while safeguarding personnel and assets. This comprehensive overview delves into the various types, applications, and maintenance strategies for Pressure Relief Valves in contemporary industrial settings.

The Role of Pressure Relief Valves in Ensuring Workplace Safety

Pressure relief valves (PRVs) play a crucial role in ensuring workplace safety across various industrial applications. According to a report by the National Fire Protection Association (NFPA), improperly functioning pressure relief devices contribute to nearly 70% of serious industrial accidents. These valves serve as critical safety components by preventing excessive pressure buildup in systems, which can lead to catastrophic failures, explosions, and injuries. In fact, the Occupational Safety and Health Administration (OSHA) emphasizes that regular maintenance and proper functioning of PRVs are essential for workplace safety, potentially reducing the risk of incidents significantly.

In addition to their safety implications, pressure relief valves are vital for operational efficiency. The U.S. Department of Labor states that the correct sizing and selection of PRVs can enhance the reliability of pressure systems, leading to lower operational costs and minimized downtime. According to a report by the International Society of Automation, over 50% of industrial facilities experience unplanned shutdowns due to valve malfunctions, which could be mitigated with better attention to PRV maintenance. Thus, investing in robust pressure relief systems not only complies with safety regulations but also promotes a more efficient and productive working environment.

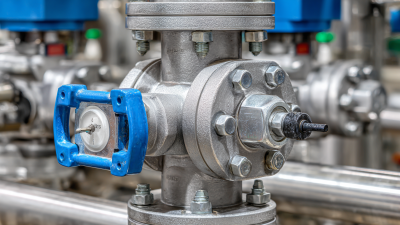

Key Factors Affecting Pressure Relief Valve Selection

When selecting pressure relief valves (PRVs) for modern industrial applications, several key factors play a crucial role in ensuring safety and efficiency. One of the most important considerations is the set pressure of the valve. According to the American Society of Mechanical Engineers (ASME), PRVs must be set to relieve pressure at or below the maximum allowable working pressure (MAWP) of the system. Utilizing advanced simulation tools can assist engineers in accurately determining the optimal set pressure, which can vary depending on the fluid type and process conditions.

Another critical factor is the material selection for the valve components. Research from the National Association of Corrosion Engineers (NACE) indicates that approximately 80% of industrial equipment experiences some form of corrosion, leading to premature equipment failure. Choosing the right materials, such as stainless steel or special alloys, can significantly enhance longevity and reliability. Additionally, the valve's size and capacity must match the specific application requirements; an undersized valve may fail to relieve excess pressure, while an oversized valve can lead to unnecessary maintenance costs and system inefficiencies, as highlighted in a study published by the Chemical Engineering Society.

Understanding the Importance of Pressure Relief Valves in Modern Industrial Applications - Key Factors Affecting Pressure Relief Valve Selection

| Factor | Description | Impact on Selection | Typical Applications |

|---|---|---|---|

| Set Pressure | The pressure at which the valve opens to relieve excess pressure. | Critical for ensuring system safety and performance. | Chemical manufacturing, oil and gas. |

| Material Compatibility | The suitability of valve materials with the fluid media. | Prevents corrosion and extends valve life. | Pharmaceuticals, food processing. |

| Flow Capacity | The maximum flow rate a valve can handle when open. | Ensures adequate pressure relief without system overload. | Power generation, water treatment. |

| Temperature Rating | The maximum and minimum temperatures at which the valve operates safely. | Determines suitability for various temperature environments. | Steam systems, petrochemical facilities. |

| Installation Orientation | The orientation in which the valve is installed (horizontal or vertical). | Affects performance and maintenance accessibility. | Manufacturing plants, HVAC systems. |

5 Common Mistakes in Pressure Relief Valve Installation

Pressure relief valves (PRVs) are critical components in industrial settings, designed to prevent excessive pressure build-up that can lead to equipment failure and safety hazards. However, improper installation can severely undermine their effectiveness. One of the most common mistakes is neglecting to consider the valve's orientation. As outlined in a 2021 report by the Safety Engineering Institute, incorrect positioning can lead to malfunction, potentially causing catastrophic events.

Another prevalent mistake is the failure to adhere to manufacturer specifications for installation. According to a study published by the American Society of Mechanical Engineers (ASME), nearly 30% of reported valve failures stem from improper sizing and selection, which emphasizes the necessity of matching the PRV to the specific application requirements. Additionally, many installations overlook the importance of removing any debris or contaminants from the piping system before installation. A clean environment is crucial, as the presence of foreign materials can severely impede valve functionality, increasing the risk of system overpressure incidents.

Maximizing Efficiency: Maintenance Tips for Pressure Relief Valves

Pressure relief valves (PRVs) are crucial in industrial settings, preventing hazardous overpressure conditions that could compromise safety and equipment integrity. According to a recent report by the National Fire Protection Association (NFPA), nearly 75% of industrial accidents involving pressurized systems can be attributed to inadequate maintenance of PRVs. Regular maintenance not only ensures compliance with safety regulations but also maximizes the operational efficiency of machinery, ultimately reducing downtime and associated costs.

To enhance the performance and longevity of pressure relief valves, a structured maintenance routine is essential. The American Society of Mechanical Engineers (ASME) recommends a quarterly inspection schedule, where valves are tested for proper functionality and wear. Lubrication of moving parts, checking for leaks, and replacing seals are critical tasks that should not be overlooked. Additionally, implementing vibration analysis technology can detect anomalies early, ensuring that any potential failure is addressed proactively. By adhering to these maintenance strategies, companies can significantly reduce the incidence of equipment failures, thereby enhancing overall productivity and safety in their operations.

Pressure Relief Valves: Maintenance Frequency and System Efficiency

This bar chart illustrates the relationship between maintenance frequency of pressure relief valves and system efficiency in industrial applications. As maintenance frequency increases, the system efficiency tends to be higher, highlighting the importance of regular inspections and upkeep.

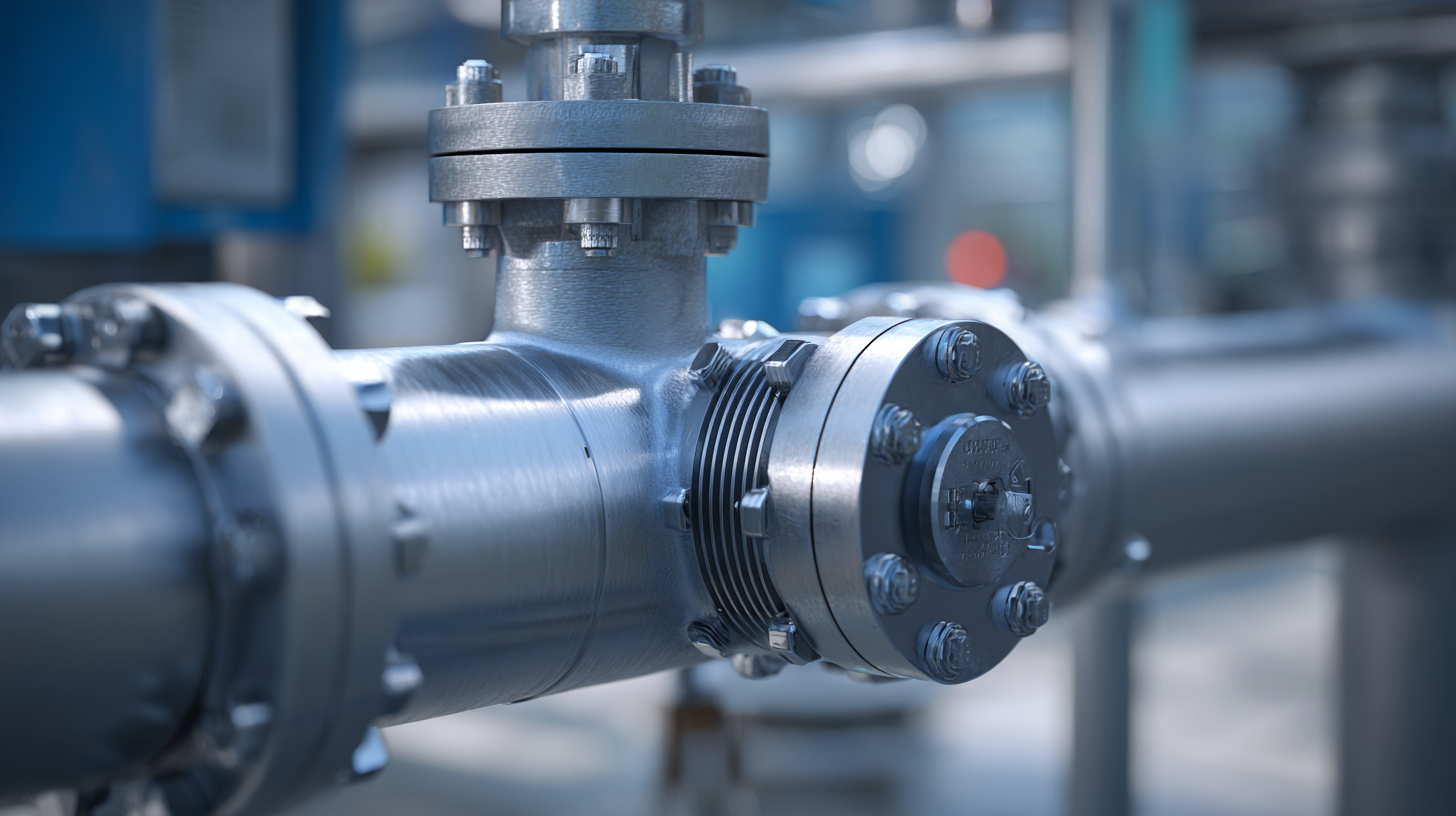

Innovative Technologies in Pressure Relief Valve Design for Industries

Pressure relief valves (PRVs) play a crucial role in many industrial applications by providing a safety measure against overpressure scenarios. The evolution of PRV technology has been marked by innovative design features that enhance their reliability and efficiency. One significant advancement is the integration of smart sensors and automation, allowing real-time monitoring and response to pressure changes. This innovation not only ensures safety but also optimizes operational processes by preventing equipment failure due to excessive pressure buildup.

Another notable advancement in PRV design is the development of materials resistant to corrosive environments. Industries such as chemical manufacturing require valves that can withstand harsh conditions while maintaining functionality. The use of advanced alloys and coatings has significantly improved the longevity of PRVs, reducing maintenance costs and downtimes. Moreover, computer-aided design (CAD) techniques enable the precise creation of valves tailored for specific applications, enhancing their effectiveness in managing pressure levels. These innovative technologies are setting new standards for safety and efficiency in industrial operations, highlighting the importance of investing in advanced pressure relief valve solutions.

Related Posts

-

Understanding the Common Issues with Pressure Relief Valve Functionality

-

Navigating Tariffs and Trade Challenges with the Best Pressure Safety Valve from China

-

Unwavering Quality of China's Trusted Best Relief Valves: A Global Manufacturing Legacy

-

Discover Premium Pressure Vacuum Relief Valves from China’s Leading Manufacturer

-

Top Strategies for Sourcing the Best Steam Pressure Relief Valve

-

Unlocking Efficiency: The Incredible Benefits of Utilizing Pressure Relief Valves in Industrial Applications