7 Secrets for Choosing the Best Water Pressure Relief Valve for Your Needs

When it comes to maintaining the safety and efficiency of plumbing systems, selecting the right Water Pressure Relief Valve is crucial. According to a recent industry report from the American Society of Plumbing Engineers, nearly 60% of water damage incidents in residential properties can be traced back to inadequate pressure regulation. These valves are designed to prevent excessive pressure build-up, which can lead to catastrophic leaks or system failures. With an increasing number of energy-efficient designs on the market, homeowners are presented with a wide range of options tailored to their specific needs. Understanding the benefits of different types of Water Pressure Relief Valves not only enhances the durability of your plumbing system but also helps in preventing costly repairs and improving overall water management. In this blog, we will unveil the seven secrets essential for choosing the best valve that aligns with your requirements.

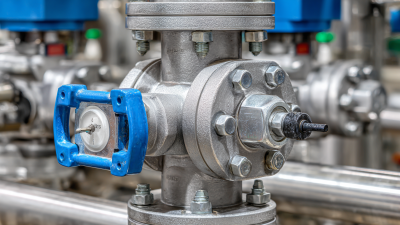

Understanding the Functionality of Water Pressure Relief Valves in Fluid Systems

Water pressure relief valves play a crucial role in maintaining the safety and efficiency of fluid systems. Their primary functionality is to prevent pressure buildup that can lead to catastrophic failures or equipment damage. By automatically releasing excess pressure, these valves ensure that the pressure remains within designated limits, allowing for optimal system operation. According to industry reports, improperly calibrated relief valves account for nearly 30% of pressure-related failures in fluid systems, highlighting the importance of selecting the right valve based on specific operational parameters.

When choosing a water pressure relief valve, it is essential to consider factors such as the system's maximum operating pressure and flow rate. Data from the American Society of Mechanical Engineers (ASME) indicates that valves should be rated for pressures that exceed the system's highest anticipated pressure by at least 25%. Moreover, understanding the media being handled is vital, as corrosive or viscous fluids may necessitate specialized valve materials. Comprehensive knowledge of these factors can significantly enhance system reliability and prolong equipment lifespan, making the selection process critical for effective fluid management.

Key Factors to Consider When Selecting Water Pressure Relief Valves

When selecting a water pressure relief valve, it's essential to consider several key factors to ensure optimal performance and safety. Firstly, the pressure rating of the valve should match your system's specifications. Too high or too low a rating can lead to inefficient operation or system failure. It's also vital to consider the flow rate, as it determines the valve's ability to handle excess pressure without compromising the system's stability. Look for valves that provide a balanced flow capacity tailored to your water usage needs.

Another important factor is material compatibility. The valve should be made from materials that resist corrosion and wear, especially if your water supply contains minerals or chemicals that could degrade the valve over time. Additionally, installation requirements and maintenance ease should be evaluated; some models may need more complex setups, while others allow for simple, quick installation. Ensuring that your chosen valve meets these criteria can help you make an informed choice that enhances the longevity and reliability of your water system.

Industry Standards and Regulations for Water Pressure Relief Valves

When choosing a water pressure relief valve, it's crucial to consider industry standards and regulations. Compliance with the latest codes from authorities like ANSI and ASME ensures not only legal adherence but also safety and efficiency in your plumbing systems. Recent discussions highlighted the importance of staying updated on these standards, as they evolve to address changing industrial needs.

Furthermore, the industrial valves market is projected to grow at a 5.1% CAGR, reaching an estimated US$ 100.9 billion by 2030, reflecting the increasing demand for efficient and reliable valve solutions across various sectors, including oil and gas. This growth signifies the importance of selecting valves that meet operational and regulatory requirements.

**Tips:** Always verify that your chosen valve complies with Section 1417 of the Safe Drinking Water Act, prohibiting lead in plumbing components. Additionally, consider implementing a cross-connection control program to prevent contamination in your potable water systems. Regularly review updates from plumbing standards meetings to stay informed on the latest safety protocols and emission regulations impacting valve selection.

Comparative Analysis of Material Types Used in Water Pressure Relief Valves

When selecting the best water pressure relief valve, understanding the material types used can significantly influence performance and durability. A comparative analysis highlights that materials like brass, stainless steel, and plastic each offer distinct advantages and disadvantages. For instance, brass valves are known for their corrosion resistance and mechanical strength, making them ideal for high-pressure applications. On the other hand, stainless steel valves provide superior resistance to harsh environments but can be costlier. According to the Pressure Reducing Valves Market report, the sector is projected to surpass USD 3,932.20 million by 2035, driven by the increasing need for efficient water management solutions.

In parallel, advancements in valve technologies are critical in addressing environmental concerns, much like the innovations we see in other sectors such as energy and materials. For example, the study on the sealing stability of rubber under hydrogen environments can inform materials engineering for water pressure relief valves, ensuring that they maintain integrity under various conditions. The ongoing comparative studies in different materials enhance the understanding and application of composite materials, similarly raising the standard for pressure relief valve applications. By leveraging insights from these analyses, engineers can make informed decisions that optimize both functionality and sustainability in water management systems.

Comparison of Material Types Used in Water Pressure Relief Valves

The Impact of Valve Sizing on Water System Efficiency and Safety

When selecting a water pressure relief valve, understanding the impact of valve sizing on your water system's efficiency and safety is crucial. The right valve size ensures that your water system operates within the desired pressure range, preventing over-pressurization that can lead to pipe bursts and costly repairs. An undersized valve may not release pressure effectively, while an oversized one could lead to inconsistent pressure control, compromising system performance.

Additionally, proper valve sizing directly affects water flow rates and energy consumption. Valves that are not appropriately sized can create turbulence and resistance within the system, leading to inefficiencies and increased energy use. This not only increases operational costs but may also shorten the lifespan of your plumbing infrastructure. By prioritizing the correct sizing of your pressure relief valve, you enhance the overall safety and efficiency of your water system, ensuring reliable performance over time.

Related Posts

-

Understanding the Common Issues with Pressure Relief Valve Functionality

-

7 Key Insights into Pressure Release Valve Performance for Global Buyers

-

Discover Premium Pressure Vacuum Relief Valves from China’s Leading Manufacturer

-

Ultimate Guide to Comparing the Best Check Valves: Features, Benefits, and Performance

-

Navigating Tariffs and Trade Challenges with the Best Pressure Safety Valve from China

-

Ultimate Guide to Choosing the Best Safety Relief Valve for Optimal Industrial Performance