What is a Sandblast Rubber Hose and How Does it Work?

The Sandblast rubber hose is an essential tool in abrasive blasting applications. It is designed specifically to handle high-pressure air and abrasive materials. This specialized hose ensures that sand and other blasting materials are conveyed safely and efficiently.

Constructed with durable rubber, the sandblast rubber hose resists wear and tear. It can withstand extreme conditions in industrial settings. However, some might underestimate its importance in maintaining equipment safety. Without proper handling, a damaged hose could lead to excessive wear or accidents.

Understanding how the sandblast rubber hose works is crucial. Operators must check for signs of wear regularly. This simple task can prevent costly repairs. While the hose serves a crucial function, it is not infallible. Regular maintenance is needed to keep it in optimal condition and ensure efficient blasting operations.

What is Sandblast Rubber Hose?

A sandblast rubber hose is a specialized tubing used for abrasive blasting. It's designed to transport sand or grit at high speeds. The exterior is durable and resistant to wear, while the interior has a smooth surface that helps minimize friction. Hoses typically come in various sizes, which influences their flow capacity and performance.

When using a sandblast rubber hose, proper care is essential. Ensure it is free from any kinks or damage. A faulty hose can lead to reduced efficiency or even accidents. Inspect your hose regularly. Sometimes, a simple visual check can reveal cracks or abrasions that need attention.

Tip: Always wear protective gear while working with sandblast hoses. Safety goggles and gloves can protect you from flying debris. Maintain a clean work area to minimize risks of tripping or tangling the hose. This small effort can enhance safety significantly. Remember, a clean workspace fosters a better focus, helping prevent mistakes.

Key Components of Sandblast Rubber Hose

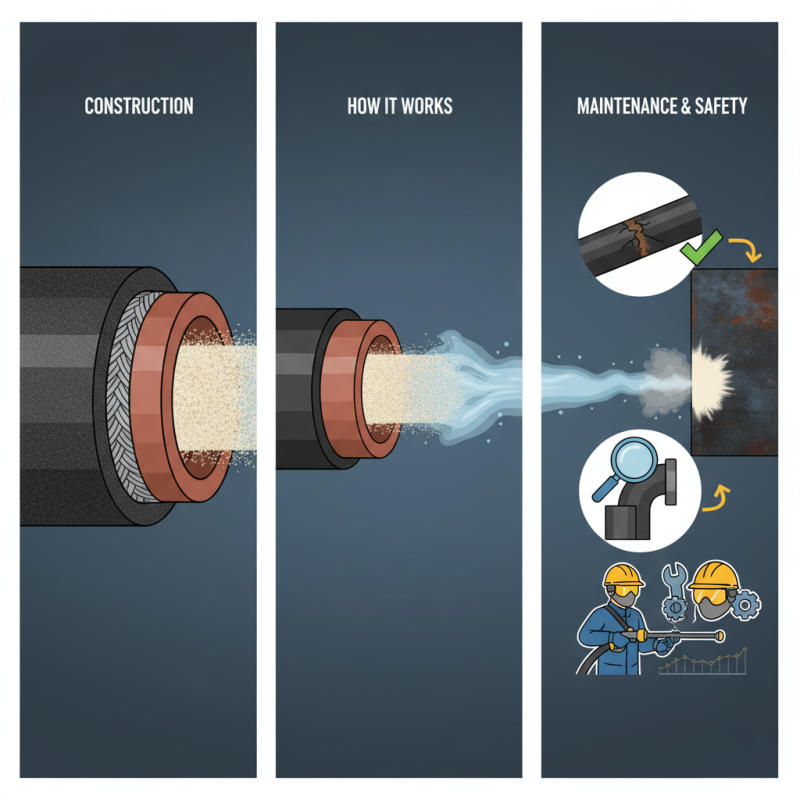

A sandblast rubber hose is a critical component in the sandblasting process. It is designed to withstand high pressure and abrasive materials. The hose is typically made from durable rubber, allowing it to flex and bend easily. The outer layer protects against wear, while the inner lining resists abrasion.

Key components of a sandblast rubber hose include the inner tube, outer layer, and fittings. The inner tube carries the abrasive material. It must be strong enough to handle the wear from the sand or other materials. The outer layer provides protection against external damage. This layer often has a rough texture to enhance grip and prevent slipping during use. Fittings on both ends ensure a secure connection to blasting equipment.

Beyond these basics, the design of a sandblast hose needs careful consideration. The diameter affects the flow rate of the materials. If it's too wide, it may be inefficient; if too narrow, it can lead to clogs. Achieving the right balance is essential for effective operation. Proper maintenance is also critical. Regular inspections can help identify wear and tear, ensuring the hose performs efficiently.

How Sandblast Rubber Hose Functions

Sandblast rubber hoses play a crucial role in various industrial applications. These hoses are specifically designed to handle abrasive materials and extreme pressure. They are typically made from a blend of rubber compounds that provide flexibility and durability. The inner lining is reinforced to withstand the wear and tear caused by abrasive particles. According to a report by the Rubber Manufacturers Association, the demand for specialized hoses has increased by over 25% in recent years, highlighting their importance in industries such as construction and manufacturing.

The function of sandblast rubber hoses is relatively straightforward. They transport sand or other abrasive media at high velocities, enabling efficient cleaning and surface preparation. The construction of these hoses often includes multiple layers, which provide additional strength and resistance to kinks. Some industry professionals note that even minor kinks can impair the flow of materials, illustrating the need for proper handling and care. Moreover, improper use may lead to increased wear, resulting in costly replacements. A recent study found that nearly 30% of equipment failures in abrasive blasting stem from hose-related issues.

While these hoses excel in performance, they also pose certain challenges. The risk of abrasion can lead to reduced lifespan if not monitored closely. Additionally, the need for compatibility with various blasting agents means careful selection is essential. Some operators have reported that using non-compliant materials can cause premature damage. Thus, understanding the specific materials and pressure ratings required is vital for optimal operation. These considerations reflect the complexity and nuances behind choosing and utilizing sandblast rubber hoses effectively.

Applications of Sandblast Rubber Hose in Industries

Sandblast rubber hoses are essential in various industries for transferring abrasive materials. They are widely used in construction, manufacturing, and maritime sectors. For instance, a report from the Industrial Rubber Products Association states that the demand for sandblast hoses has surged by 15% in recent years, driven by increased construction projects.

In construction, these hoses facilitate effective surface preparation. They are used for applications like removing paint and rust from metals. The ability to withstand high-pressure air and abrasive materials is crucial. Additionally, the automotive industry relies on sandblast hoses in finishing operations. A recent study estimates that approximately 30% of metalworking companies have adopted sandblasting to enhance product quality.

However, operators sometimes overlook the importance of regular hose inspection. Worn-out hoses can lead to hazardous leaks and inefficiencies. Safety data reveals that 42% of workplace incidents in the manufacturing sector result from equipment failure. Proper maintenance is therefore not just a suggestion but a necessity. Integrating routine checks into operational protocols can significantly decrease risks and improve performance.

Maintenance and Care for Sandblast Rubber Hose

Maintaining a sandblast rubber hose is vital for ensuring efficient operation and longevity. These hoses work under high pressure, often reaching up to 150 PSI, depending on the specific application. Regular inspection is key. Check for wear, cracks, and leaks. A hose in poor condition can result in downtime and costly repairs.

Proper care starts with cleaning. After each use, clear out any abrasive materials to prevent buildup. It is essential to store the hose in a cool, dry place. Exposure to extreme temperatures can deteriorate the rubber. Avoid sharp bends, as they can create weak points.

Tips for extending hose life include using proper fittings and keeping connections tight. When storing, coil the hose loosely instead of tightly. This prevents kinks and stress. According to industry reports, properly maintained hoses can last up to 50% longer. Pay attention to factors like environmental exposure and frequency of use. Each detail matters. Taking these steps can save time and money in the long run.

What is a Sandblast Rubber Hose and How Does it Work? - Maintenance and Care for Sandblast Rubber Hose

| Feature | Details |

|---|---|

| Material | Rubber reinforced with textile |

| Operating Temperature | -20°C to +70°C |

| Application | For sandblasting and surface preparation |

| Pressure Rating | Up to 300 psi |

| Diameter Options | 1/2 inch, 3/4 inch, 1 inch |

| Maintenance Tips | Regular inspection for wear, proper storage management, and cleaning after use |

| Lifespan | 5 to 10 years depending on usage and care |