Navigating Tariffs and Trade Challenges with the Best Pressure Safety Valve from China

In an increasingly complex global trade environment, navigating tariffs and trade challenges has become crucial for manufacturers worldwide. Amidst the trade tensions and reciprocal tariffs between China and the United States, the Chinese manufacturing sector has demonstrated remarkable resilience and growth. A key player in this sector is the Pressure Safety Valve, an essential component across various industries that ensures safety and efficiency. Despite the hurdles posed by tariffs, Chinese manufacturers have leveraged their innovative technologies and cost-effective production methods to maintain competitiveness in the global market. This blog will explore how these manufacturers are thriving amidst these challenges, enhancing their reputation for quality and reliability while providing insight into the mechanisms behind Pressure Safety Valves and their vital role in maintaining safety standards in industrial applications.

Challenges of Trade Tariffs in the Pressure Safety Valve Industry

The pressure safety valve (PSV) industry has been significantly impacted by trade tariffs, especially in the context of international trade dynamics. According to a recent report by ResearchAndMarkets, the global pressure safety valve market is projected to reach $5.3 billion by 2025, growing at a CAGR of 4.5%. However, rising tariffs on imported materials and components can impose extra costs on manufacturers, leading to increased prices for end-users. The U.S. and China, two major players in this industry, face ongoing tariff disputes that specifically affect the import and export of PSV components, causing uncertainty in pricing and supply chains.

Moreover, an analysis by MarketsandMarkets indicates that the Asia-Pacific region, particularly China, is poised for considerable growth, attributed to its robust manufacturing capabilities and demand for safety equipment. However, the 25% tariff hike on certain industrial goods can disrupt this trend, forcing manufacturers to either absorb the costs or pass them on to consumers. This not only affects profitability but can also lead to a potential decrease in market share for businesses that fail to adapt to the evolving trade landscape. The challenge lies in navigating these tariffs while still delivering high-quality and cost-effective pressure safety valves to the global market.

Impact of US-China Tariffs on Manufacturing and Export Trends

The ongoing trade tensions between the U.S. and China have significantly impacted manufacturing and export trends in both countries, particularly in sectors reliant on pressure safety valves. According to a report by the American Society of Mechanical Engineers, the implementation of tariffs has led to an estimated 20% increase in cost for U.S. manufacturers who rely on imported components, pushing many companies to reconsider their supply chains. With China being one of the largest producers of pressure safety valves, the tariffs have not only increased production costs in the U.S. but also prompted Chinese manufacturers to adapt their strategies to retain market share.

In response to these tariffs, the Chinese valve industry has seen a shift towards enhancing the quality and competitiveness of its products, resulting in a 15% increase in export volume in 2022 despite the trade barriers. Furthermore, industry analysis by MarketsandMarkets suggests that the global pressure safety valve market is expected to reach $5.67 billion by 2026, indicating resilient demand despite challenges. As manufacturers navigate through these turbulent waters, the choice of sourcing high-quality pressure safety valves from China remains a strategic avenue to mitigate costs and maintain operational efficiency in the evolving landscape of U.S.-China trade relations.

Evaluating the Growth of China's Pressure Safety Valve Market Amid Tariff Pressures

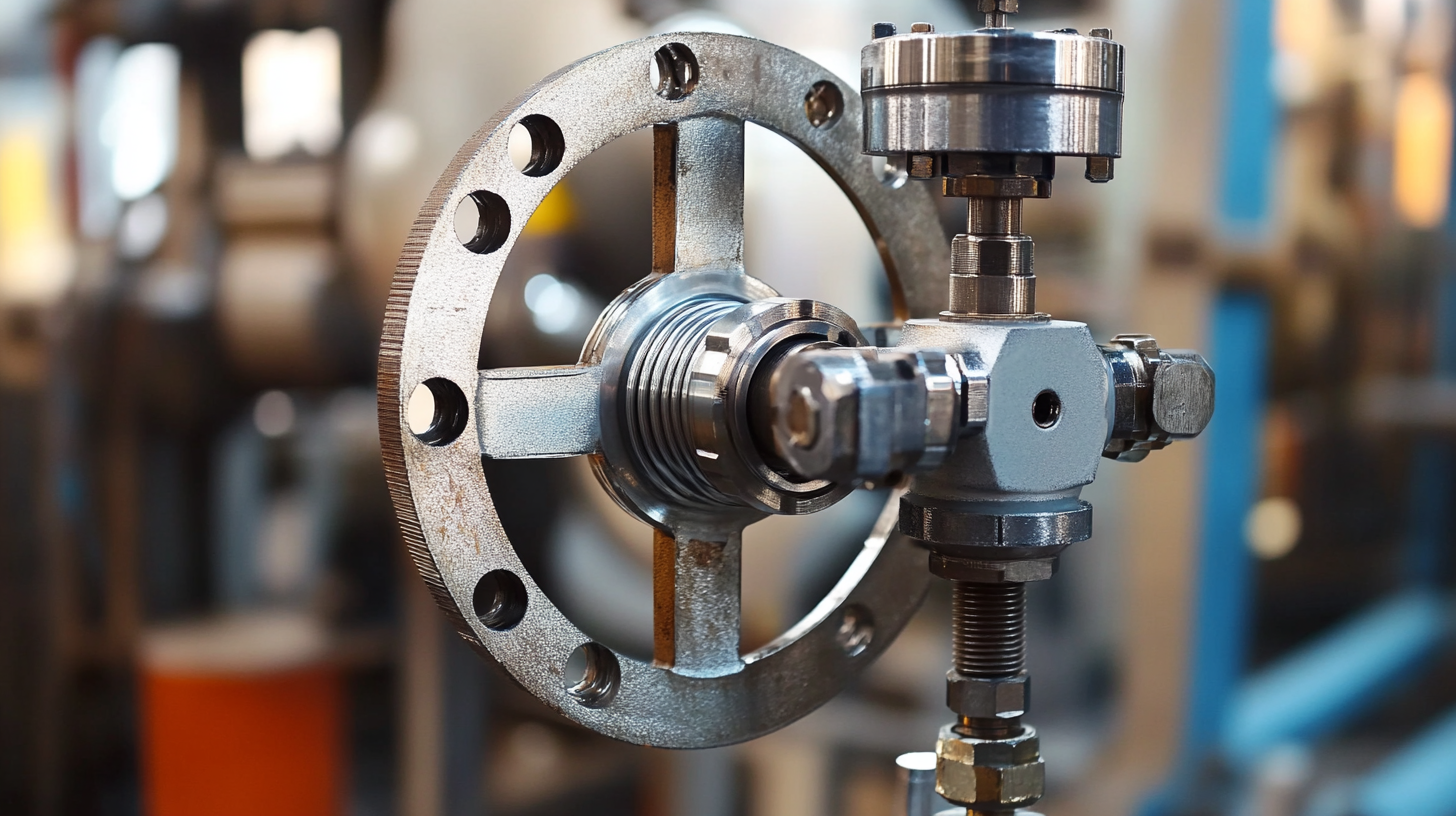

China's pressure safety valve market has been experiencing substantial growth despite the challenges posed by international tariffs. As global trade tensions continue to affect various industries, manufacturers in China are strategically adapting to maintain their competitive edge. The pressure safety valve, a critical component for ensuring operational safety in various sectors such as oil and gas, power generation, and chemical processing, has witnessed a surge in domestic production capabilities.

In light of these tariff pressures, Chinese manufacturers are increasingly focusing on innovation and quality improvements to align with global standards. The investment in research and development is not only enabling them to enhance product performance but also to comply with stringent safety regulations required by international markets. As a result, China is positioning itself as a reliable source of high-quality pressure safety valves, overcoming obstacles through strategic alliances and optimizing supply chains. This positive trend reflects the resilience of the Chinese market and its ability to navigate the complexities of global trade.

Strategies for Sourcing High-Quality Pressure Safety Valves from China

Sourcing high-quality pressure safety valves from China requires a well-thought-out strategy, particularly in the face of increasing tariffs and trade challenges. First and foremost, it's essential to perform thorough research on potential suppliers. This includes assessing their manufacturing capabilities, quality control processes, and industry certifications. Engaging with suppliers that have a proven track record of compliance with international standards can significantly minimize risks and ensure product reliability.

Another effective strategy is to establish direct communication with manufacturers. This can be done by visiting production facilities or participating in trade fairs in China. Such interactions allow buyers to inspect the manufacturing process, assess quality firsthand, and build strong relationships. Additionally, leveraging the experience of local sourcing agents can help navigate complex regulations and identify reputable manufacturers, facilitating smoother transactions and better negotiation terms. By implementing these strategies, businesses can enhance their procurement process and secure top-notch pressure safety valves, mitigating the impact of tariffs and trade uncertainties.

Industry Insights: Performance Metrics and Demand Forecasts for Pressure Safety Valves

As the pressure safety valve (PSV) market continues to grow amidst varying tariffs and trade challenges, understanding performance metrics and demand forecasts is crucial for industry stakeholders. Current market analysis indicates a compound annual growth rate (CAGR) of approximately 5.6% from 2021 to 2028, driven by increasing demand in sectors such as oil and gas, chemical manufacturing, and power generation. According to a recent report by MarketsandMarkets, the total market size for PSVs is projected to reach $3.3 billion by 2028, highlighting robust growth driven by safety regulations and technological advancements.

When considering the best PSVs from China, manufacturers are advised to focus on certain performance metrics, including pressure ranges, reliability, and material durability. It's essential to choose valves that meet or exceed API and ASME standards to ensure compliance and safety. Additionally, forecasts suggest a surge in demand for smart PSVs equipped with IoT capabilities, enabling real-time monitoring and predictive maintenance.

**Tip:** Ensure the PSV you select is compatible with specific industry requirements. Regularly reviewing performance against established benchmarks can help maintain optimal safety levels.

**Tip:** Keep an eye on evolving regulatory requirements in your region, as these can impact the demand for specific PSV designs and functionalities.