7 Essential Tips for Understanding Pressure Control Valves in Industrial Applications

In the realm of industrial applications, the efficient management of fluid systems is crucial, and Pressure Control Valves (PCVs) play a pivotal role in this process. According to a recent report from the Global Industry Analysts, the global market for pressure control valves is projected to reach USD 6.5 billion by 2025, reflecting their integral function across various sectors, including oil and gas, water management, and manufacturing. Understanding the intricacies of PCVs is essential for optimizing operations and ensuring safety within these industries. This article presents seven essential tips to help professionals grasp the fundamental concepts of pressure control valves, addressing not only their operational principles but also their sizing, selection, and maintenance within complex systems. Proper knowledge and application of PCVs can lead to enhanced efficiency, reduced operational costs, and increased safety, paving the way for better performance in industrial environments.

Understanding the Fundamental Principles of Pressure Control Valves in Industry

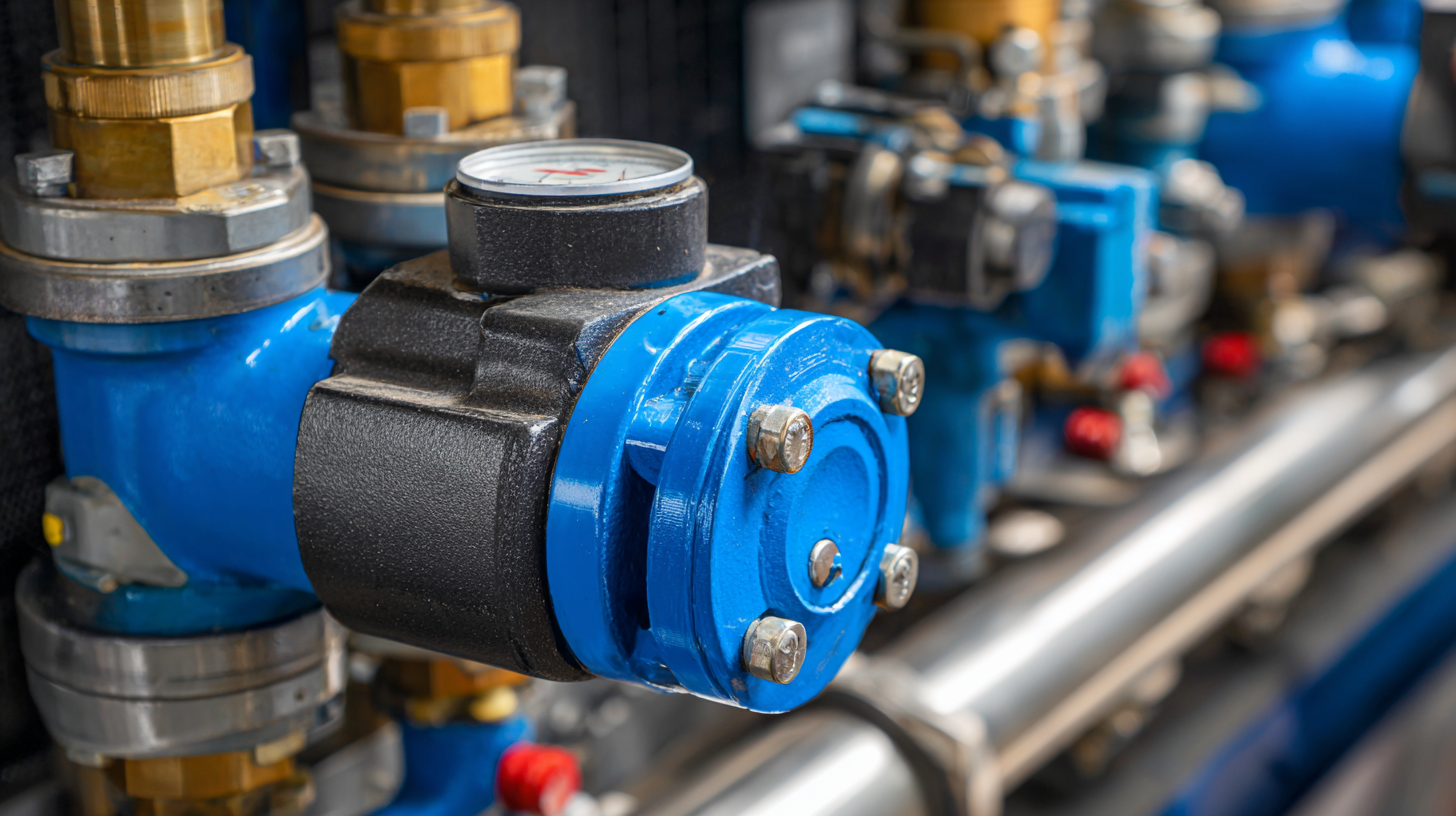

Pressure control valves play a crucial role in industrial applications by regulating the pressure within hydraulic and pneumatic systems. Understanding their fundamental principles is essential for maintaining system efficiency and safety. These valves operate by automatically adjusting the flow of fluid to stabilize pressure levels, ensuring that they remain within desired parameters. The ability to modulate pressure effectively helps prevent equipment damage and system failures, which can result in costly downtimes.

One of the key principles behind pressure control valves is the differential pressure concept. This principle states that the valve opens or closes based on the difference between the upstream and downstream pressures. When the upstream pressure exceeds the set point, the valve responds by partially or completely opening to decrease the pressure downstream. Additionally, factors such as valve sizing, response times, and the characteristics of the fluid being controlled can significantly influence performance. A comprehensive understanding of these principles allows engineers and technicians to select and implement the right pressure control valves for specific industrial applications, optimizing operational reliability and performance.

7 Essential Tips for Understanding Pressure Control Valves in Industrial Applications

| Tip Number | Tip Description | Application Scenario | Benefits |

|---|---|---|---|

| 1 | Understand the Basics of Pressure Regulation | Chemical processing | Improved system stability |

| 2 | Select the Right Type of Valve | Water treatment facilities | Increased efficiency |

| 3 | Regular Maintenance and Inspections | Oil and gas industry | Reduction in unexpected downtimes |

| 4 | Calibrate Your Pressure Control Settings | Pharmaceutical production | Quality assurance |

| 5 | Understand Fluid Dynamics | Automotive testing | Enhanced performance analysis |

| 6 | Properly Size Your Valves | Food processing | Cost savings on materials |

| 7 | Train Staff on Valve Operation | Manufacturing plants | Improved safety |

The Role of Pressure Control Valves in Regulating System Pressure

Pressure control valves play a crucial role in maintaining optimal pressure levels in various industrial applications. These valves help regulate system pressure, ensuring that operations remain efficient and safe. For instance, incorporating intelligent pressure management techniques can significantly reduce water losses and prevent pipe bursts. A recent analysis demonstrated that utilizing pressure reducing valves can lead to a reduction in non-revenue water, ultimately saving resources and improving system reliability.

Pressure control valves play a crucial role in maintaining optimal pressure levels in various industrial applications. These valves help regulate system pressure, ensuring that operations remain efficient and safe. For instance, incorporating intelligent pressure management techniques can significantly reduce water losses and prevent pipe bursts. A recent analysis demonstrated that utilizing pressure reducing valves can lead to a reduction in non-revenue water, ultimately saving resources and improving system reliability.

To effectively understand and utilize pressure control valves, consider these essential tips: First, regularly monitor adjustments to pressure reducing steam valves to ensure they function correctly. Accurate control mechanisms enhance performance and reliability, which is vital in high-demand environments. Secondly, keep abreast of innovations in electro-pneumatic pressure regulators, which are known to provide high levels of accuracy due to electronic controls. This precision is essential for tasks requiring consistent pressure levels and can drastically improve operational efficiency.

Furthermore, ongoing innovations in valve technology signify the need for industries to adapt. For example, recent developments in electrohydraulic pressure control systems have highlighted both challenges and potential breakthroughs. Being aware of these advancements can enable industries to choose the most suitable pressure control solutions, improving performance and safety across various applications.

Common Types of Pressure Control Valves and Their Applications

Pressure control valves (PCVs) play a crucial role in various industrial applications, particularly in oil and gas drilling operations. Understanding the common types of pressure control valves and their specific applications is paramount for optimizing performance and safety. Among the most prevalent types are conventional blowout preventers (BOPs), subsea BOPs, and other specialized configurations like dual barrier systems. Each of these types serves distinct functions, such as managing well pressure or preventing blowouts, making them essential components in any drilling project.

In recent years, the market for pressure control systems has seen significant growth, driven by the increasing demand for energy and advancements in drilling technologies. Reports indicate that the global pneumatic component market is set to surpass $16.57 billion by 2025, with a compound annual growth rate (CAGR) of over 5.3% from 2026 to 2035. This growth is fueled by rising initial costs and the necessity for efficient pressure management systems.

When dealing with pressure control valves, it is important to prioritize regular maintenance checks to ensure their optimal functionality. Furthermore, understanding the specific requirements of the application can help in selecting the right type of valve. Keeping abreast of industry trends and advancements in technology can also significantly enhance operational efficiency and safety in the field.

Key Factors to Consider When Selecting Pressure Control Valves

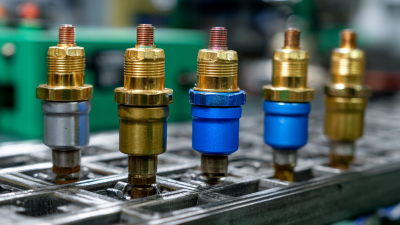

When selecting pressure control valves for industrial applications, several key factors should be considered to ensure optimal performance and safety. The valve's material is crucial; for instance, according to a report by the International Journal of Engineering Research and Applications, materials such as stainless steel or brass are preferable in corrosive environments, as they offer better durability and resistance. Furthermore, understanding the valve's pressure rating is essential. Industry standards from the American Society of Mechanical Engineers (ASME) indicate that selecting a valve with a suitable pressure rating can prevent catastrophic failures, which are responsible for approximately 40% of industrial accidents linked to piping systems.

Another significant factor is the valve type. Various designs, such as proportional or relief valves, serve different functions within a system. According to a survey conducted by the Fluid Controls Institute, nearly 30% of industrial facilities report that improper valve selection contributed to downtime and inefficiency. Additionally, ensuring compatibility with flow rate and design specifications can enhance system efficiency. The relationship between flow and pressure control is critical; anecdotal evidence suggests that optimizing these elements can improve energy consumption by up to 25%, highlighting the substantial impact of informed valve selection in an industrial setting.

Understanding Pressure Control Valves: Key Selection Factors

This chart illustrates the importance rating of key factors to consider when selecting pressure control valves in industrial applications. Each factor is rated on a scale from 1 to 10, indicating its significance in the selection process.

Maintaining and Troubleshooting Pressure Control Valves for Optimal Performance

Pressure control valves are critical components in various industrial systems, ensuring that pressure levels remain within designated limits for safe and efficient operations. Maintaining these valves is essential to prevent malfunctions that can lead to costly downtime and safety hazards. Regular inspection of the valve body for signs of wear, leaks, or corrosion is vital. Additionally, checking the actuator and adjusting it as necessary can enhance response time and accuracy, ensuring the valve performs optimally under varying conditions.

Troubleshooting pressure control valves involves a systematic approach to identifying issues that may arise during operation. If a valve is not responding as expected, one should first examine the control signals and the integrity of the pneumatic or hydraulic lines connected to it. If the valve is sticking or not closing completely, it might be a sign of debris within the system, which necessitates immediate cleaning. Keeping detailed records of maintenance activities can also aid in recognizing patterns that highlight recurring problems, allowing for proactive measures to be implemented before they escalate into significant issues.

Related Posts

-

Essential Checklist for Sourcing the Best Pressure Release Valve: What Every Global Buyer Needs

-

Exploring Innovative Alternatives to Best Pressure Safety Valves in Industrial Applications

-

Unlocking Opportunities with Safety Relief Valves at the Guangzhou Trade Fair 2025

-

Ultimate Guide to Choosing the Best Safety Relief Valve for Optimal Industrial Performance

-

Unwavering Quality of China's Trusted Best Relief Valves: A Global Manufacturing Legacy

-

Unlocking Comfort: The Benefits of the Best Pressure Relief Solutions for Global Procurement