Essential Tips for Choosing Die Casting Molds for Your Projects?

In the fast-evolving landscape of manufacturing, selecting the right Die Casting Molds is crucial. Research from the International Die Casting Association indicates that proper mold selection can enhance production efficiency by up to 30%. As expert John Smith aptly states, “The right mold is the backbone of successful die casting projects.”

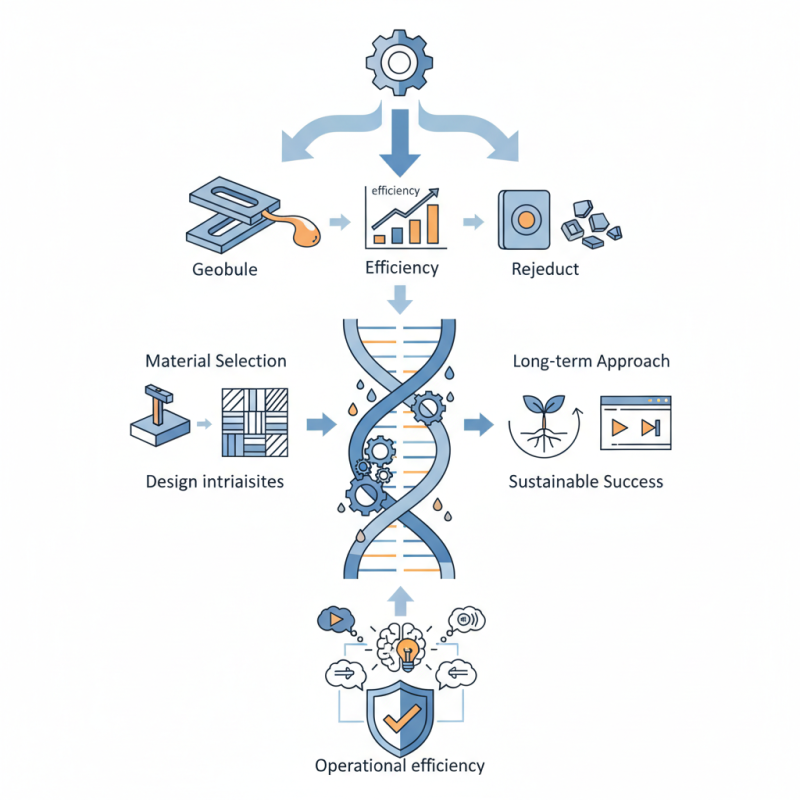

Die Casting Molds influence product quality and cost-effectiveness. A poorly chosen mold can lead to defects, increased waste, and higher costs. The market is filled with options that sometimes confuse manufacturers. It's vital to understand factors like material selection and design intricacies.

Navigating the complexities of mold design is not always straightforward. Various techniques can impact the lifespan and integrity of molds. A long-term approach is essential for sustainable success. Reflecting on previous projects, many manufacturers realize missed opportunities due to suboptimal choices in molds. Choosing wisely can lead to significant advancements in both product quality and operational efficiency in the die casting industry.

Understanding Die Casting: Overview of Molding Techniques and Materials

Die casting is a vital process in manufacturing. It is used to create precise and complex parts. Various molding techniques are available, including gravity and low-pressure die casting. These methods cater to different needs, allowing flexibility in production.

Materials play a crucial role. Aluminum accounts for about 80% of die casting in the automotive industry. However, zinc is gaining popularity due to its excellent mechanical properties. A recent industry report indicated that the global die casting market is projected to reach $20 billion by 2027. This highlights the importance of selecting the right material for specific applications.

Choosing the right mold is not always straightforward. Factors such as cost, lead time, and material compatibility come into play. Mold design is often overlooked. Poor design can lead to defects and increased production costs. Reflection on past projects can aid in making better choices moving forward. A continuous improvement mindset is essential in this ever-evolving industry.

Key Factors in Selecting Die Casting Molds for Enhanced Product Quality

Choosing the right die casting molds is crucial for producing high-quality products. Various factors come into play when selecting these molds. One essential aspect is the material used. Research indicates that aluminum molds offer faster cooling rates, enhancing production efficiency by up to 30%. Conversely, steel molds provide durability but may result in longer cycle times.

Another critical factor is the mold design itself. Complex geometries can be challenging to execute. According to industry reports, molds with intricate designs can lead to up to 15% more scrap material if not carefully managed. This emphasizes the need for precision in the design phase. Additionally, cooling channels must be strategically placed to prevent hot spots, which can compromise product integrity.

Furthermore, the selection process shouldn’t overlook the cost implications. While cheaper molds may seem tempting, they often require more frequent replacements. Data suggests that investing in higher-quality molds can lead to a 25% reduction in total production costs over time. This is an area where reflecting on short-term savings versus long-term efficiency is crucial for project success.

Analyzing Material Compatibility: Aluminum, Zinc, and Magnesium Alloys

When selecting die casting molds, understanding material compatibility is crucial. Aluminum, zinc, and magnesium alloys each offer unique benefits and constraints. Aluminum, for instance, is widely used due to its excellent strength-to-weight ratio. According to a recent industry report, aluminum shapes can be 35% lighter than steel while maintaining similar strength levels. This makes aluminum a popular choice for automotive and aerospace applications.

Zinc alloys, on the other hand, are known for their excellent fluidity and detail in complex mold designs. They often provide better surface finishes, which reduces post-processing needs. Reports indicate that zinc die castings can have a production rate of 1000-1500 parts per hour. This makes them efficient for high-volume production. However, the cost can be a concern for some manufacturers.

Magnesium alloys are gaining traction due to their lightweight and high strength. They possess a lower melting point, which can lead to energy savings during the die casting process. Nonetheless, magnesium's susceptibility to corrosion might require additional surface treatments. Each material comes with its own set of challenges, and making the right choice depends on project specifications, production goals, and budget constraints. Understanding these nuances is essential in the mold selection process.

Evaluating Cost-Effectiveness in Die Casting Mold Design and Production

When evaluating cost-effectiveness in die casting mold design and production, one must consider various factors. The initial cost of a mold may seem high, but its longevity can lead to savings over time. An expensive mold might produce a higher volume of parts, lowering the cost per unit. This balance between cost and efficiency is crucial for project success.

Tips: Always assess your production needs. A mold designed for high volume will be different from one for small batches. Think about the materials you will use. Some materials may lower immediate costs but could lead to higher maintenance expenses later. It’s vital to involve engineers early in the design process. They can identify potential issues that could affect cost down the line.

Ensure your chosen design can adapt to future changes. Markets evolve, and your mold should allow for minor modifications. Remember, defects in molds can lead to wasted resources. Reflect on the production process. Are there steps that could be streamlined to enhance cost-effectiveness? Testing and optimizing every stage is essential for a successful project.

Cost-Effectiveness in Die Casting Mold Design and Production

The Role of Precision and Tolerances in Successful Die Casting Projects

Choosing the right die casting molds is crucial for any successful project. Precision plays a significant role in achieving the desired outcomes. Tolerances in die casting can impact the final product's quality and fit. Tight tolerances facilitate better assembly and functionality, reducing the risk of errors.

When selecting molds, consider the specifications carefully. Analyze the intended application, material, and complexity of the part. A basic mold can sometimes lead to unforeseen issues. Small flaws in tolerance can magnify in the final product. Sometimes, it’s easy to overlook minor details. Pay close attention to the shape and surface finish needed.

Here are a few tips to keep in mind. Always verify the capabilities of your chosen mold manufacturer. Understand their engineering processes. It can prevent costly mistakes later. Regular communication is also vital. Discuss any concerns related to design and yield.

Remember, the success of your die casting depends on these foundational elements. Addressing them early could save time and resources, leading to a smooth production phase.