Unlocking Efficiency: The Incredible Benefits of Utilizing Pressure Relief Valves in Industrial Applications

In today's rapidly evolving industrial landscape, optimizing operational efficiency is paramount, and one crucial component in achieving this is the Pressure Relief Valve (PRV). According to a report by the International Journal of Pressure Vessels and Piping, improper management of pressure in industrial systems can lead to catastrophic failures, resulting in financial losses averaging over $5 million per incident. The strategic implementation of PRVs not only enhances safety by preventing overpressure situations but also significantly reduces downtime and maintenance costs. Furthermore, research from the American Society of Mechanical Engineers highlights that industries employing PRVs can achieve up to a 30% improvement in safety compliance and overall system reliability. As businesses seek innovative solutions to streamline operations while adhering to regulatory standards, understanding and leveraging the benefits of Pressure Relief Valves becomes increasingly essential.

In today's rapidly evolving industrial landscape, optimizing operational efficiency is paramount, and one crucial component in achieving this is the Pressure Relief Valve (PRV). According to a report by the International Journal of Pressure Vessels and Piping, improper management of pressure in industrial systems can lead to catastrophic failures, resulting in financial losses averaging over $5 million per incident. The strategic implementation of PRVs not only enhances safety by preventing overpressure situations but also significantly reduces downtime and maintenance costs. Furthermore, research from the American Society of Mechanical Engineers highlights that industries employing PRVs can achieve up to a 30% improvement in safety compliance and overall system reliability. As businesses seek innovative solutions to streamline operations while adhering to regulatory standards, understanding and leveraging the benefits of Pressure Relief Valves becomes increasingly essential.

Benefits of Enhanced Safety: How Pressure Relief Valves Mitigate Industrial Risks

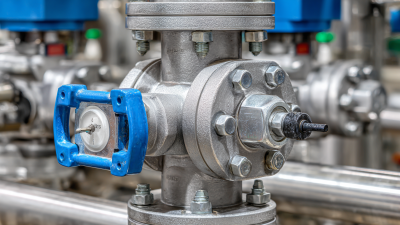

In the world of industrial operations, safety is paramount. Pressure relief valves (PRVs) serve as a critical line of defense against potential hazards by managing excess pressure within systems. These ingenious devices are designed to automatically release pressure when it exceeds a predetermined limit, thereby preventing catastrophic failures. The implementation of PRVs not only protects equipment but also ensures the safety of personnel, minimizing the risks of explosions or leaks that could result from uncontrolled pressure buildup.

Moreover, the utilization of pressure relief valves enhances overall operational efficiency. By maintaining optimal pressure levels, PRVs help to prolong the lifespan of machinery and reduce maintenance costs. This reliability translates to fewer interruptions in production, allowing for a smoother workflow and improved productivity. In addition, the peace of mind that comes with knowing that an effective safety mechanism is in place empowers workers to focus on their tasks without the looming concern of potential industrial accidents. Investing in quality pressure relief valves is a proactive approach to mitigating industrial risks and fostering a safe working environment.

Unlocking Efficiency: The Benefits of Pressure Relief Valves in Industrial Applications

Maximizing Operational Efficiency: The Role of Pressure Relief Valves in Process Optimization

In industrial operations, maintaining optimal pressure levels is crucial for maximizing efficiency and ensuring safety. Pressure relief valves (PRVs) play a vital role in this context, functioning as safety devices designed to regulate excess pressure in various systems. According to a recent report by the American Society of Mechanical Engineers (ASME), improperly functioning pressure relief systems can lead to catastrophic failures, costing industries an estimated $1 billion annually in downtime and damages. By effectively managing pressure fluctuations, PRVs not only prevent failures but also enhance overall process optimization.

To maximize operational efficiency, it is essential to select the right type of pressure relief valve for your specific application. For instance, steam systems often require different specifications compared to chemical processing applications. Regular maintenance and testing of PRVs ensure they operate within the designed parameters, significantly reducing the risk of leaks or replacements. Industry studies indicate that organizations implementing routine checks can reduce maintenance costs by up to 30%, leading to substantial savings.

Tip: Keep a detailed log of your PRVs' performance and maintenance history. This data can help you identify patterns that may lead to proactive improvements. Additionally, consider involving your engineering team in assessing the conditions under which your valves operate to ensure they are adequately specified for their application.

Cost Savings Analysis: Reducing Maintenance and Downtime with Pressure Relief Valves

In industrial applications, pressure relief valves (PRVs) play a critical role in enhancing operational efficiency and reducing costs. One significant area where PRVs contribute is maintenance and downtime management. According to a report by Grand View Research, the global pressure relief valve market is projected to reach $5.72 billion by 2025, driven largely by the demand for improved safety standards and system reliability. Efficiently designed PRVs help minimize the risk of equipment failure, thereby reducing the frequency and cost of maintenance activities.

Furthermore, industries that incorporate PRVs can experience substantial cost savings. The Hydraulic Institute estimates that the integration of robust pressure relief systems can lead to a 10-20% reduction in operational downtime. By preventing equipment pressure spikes, which can lead to unexpected shutdowns, companies can maintain productive operations and avoid costly repairs. Additionally, the cumulative savings from minimized downtime and reduced maintenance can translate into millions of dollars annually for large industrial facilities, making PRVs not just a safety measure but a strategic financial decision.

Unlocking Efficiency: The Incredible Benefits of Utilizing Pressure Relief Valves in Industrial Applications - Cost Savings Analysis: Reducing Maintenance and Downtime with Pressure Relief Valves

| Application | Total Annual Cost Without PRVs | Total Annual Cost With PRVs | Annual Savings | Downtime Reduction (%) | Maintenance Frequency Reduction (%) |

|---|---|---|---|---|---|

| Chemical Processing | $150,000 | $110,000 | $40,000 | 30% | 25% |

| Oil and Gas Extraction | $200,000 | $150,000 | $50,000 | 25% | 20% |

| Food and Beverage | $120,000 | $90,000 | $30,000 | 20% | 15% |

| Pharmaceutical | $250,000 | $180,000 | $70,000 | 40% | 30% |

Environmental Impact: How Pressure Relief Valves Contribute to Sustainable Industrial Practices

Pressure relief valves (PRVs) play a pivotal role in promoting sustainable industrial practices by significantly reducing environmental impacts associated with industrial processes. Recent advancements in PRV technology have demonstrated their ability not only to enhance safety and operational efficiency but also to minimize emissions—an essential factor for industries aiming for greener operations. For instance, research indicates that the implementation of advanced monitoring systems alongside PRVs can lead to a substantial reduction in greenhouse gas emissions, with some studies citing reductions of up to 30% in specific applications.

Pressure relief valves (PRVs) play a pivotal role in promoting sustainable industrial practices by significantly reducing environmental impacts associated with industrial processes. Recent advancements in PRV technology have demonstrated their ability not only to enhance safety and operational efficiency but also to minimize emissions—an essential factor for industries aiming for greener operations. For instance, research indicates that the implementation of advanced monitoring systems alongside PRVs can lead to a substantial reduction in greenhouse gas emissions, with some studies citing reductions of up to 30% in specific applications.

Furthermore, the importance of controlling industrial discharges cannot be overstated, as pollution management has become a foremost global concern. Analytical methods for assessing environmental contaminants in water and wastewater underscore the necessity of robust safety mechanisms. By ensuring that systems remain within operational safe limits, pressure relief valves mitigate the risk of overflow and accidental discharges, which are critical in protecting water quality and maintaining ecological balance.

Amidst the ongoing revolution toward hydrogen energy systems, PRVs are also integral in facilitating the transition by managing pressure levels in hydrogen production processes, thus supporting the overall sustainability objectives of industries. As the demand for cleaner energy sources grows, the contribution of these valves to reducing the ecological footprint of manufacturing and energy production will be paramount in achieving a sustainable future.

Regulatory Compliance: Meeting Industry Standards with Effective Pressure Relief Valve Solutions

In today's industrial landscape, regulatory compliance is of utmost importance. Industries are required to adhere to stringent safety standards to protect workers, equipment, and the environment. One of the most effective ways to meet these standards is through the installation of pressure relief valves (PRVs). These critical devices are designed to prevent excessive pressure buildup in tanks, pipes, and other systems, thereby ensuring safe operational conditions.

Pressure relief valves not only help in maintaining compliance with government regulations but also enhance overall system reliability. By automatically releasing pressure when it exceeds preset levels, PRVs reduce the risk of catastrophic failures, equipment damage, and potential injuries. This proactive measure aligns with regulatory frameworks, such as OSHA and EPA guidelines, which mandate safe operational practices in various industries. Furthermore, regular maintenance and testing of PRVs ensure they function correctly, providing an added layer of safety and compliance assurance.

Incorporating effective pressure relief valve solutions offers a dual advantage: meeting industry standards while optimizing operational efficiency. Companies can avoid significant financial penalties from non-compliance, as well as the costs associated with accidents and equipment downtime. As industries evolve, ensuring that pressure relief systems are up-to-date with the latest technological advancements and regulatory requirements is paramount for long-term success.

Related Posts

-

Understanding the Common Issues with Pressure Relief Valve Functionality

-

Navigating Tariffs and Trade Challenges with the Best Pressure Safety Valve from China

-

Discover Premium Pressure Vacuum Relief Valves from China’s Leading Manufacturer

-

Top Strategies for Sourcing the Best Steam Pressure Relief Valve

-

The Definitive Ultimate Guide to Selecting the Best Pilot Valve for Your Needs

-

Exploring Innovative Alternatives to Best Pressure Safety Valves in Industrial Applications