2026 Top Electric Ball Valves What You Need to Know?

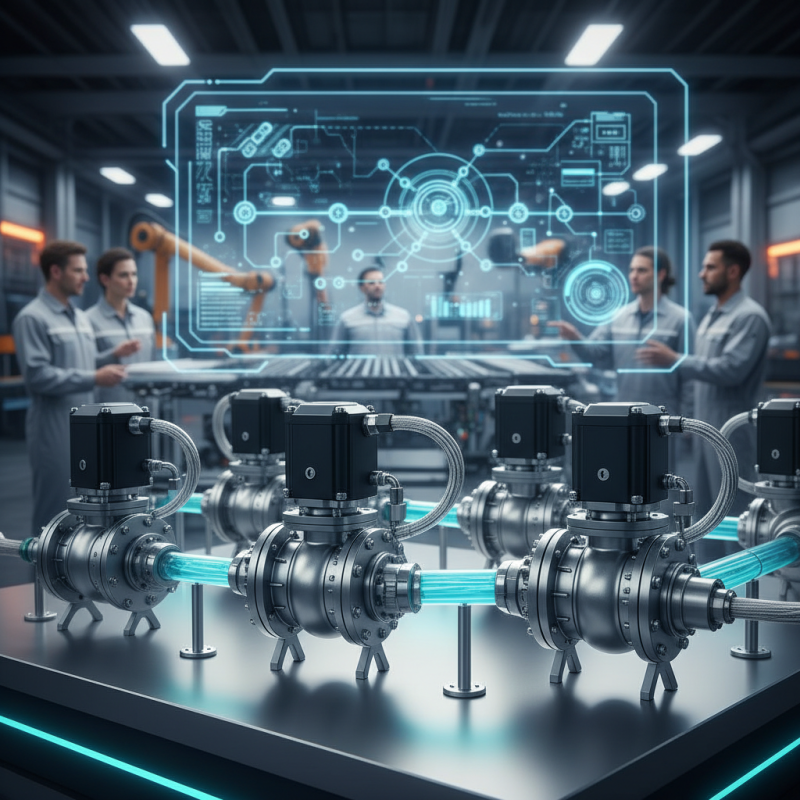

The rise of Electric Ball Valves reshapes industries, promising efficiency and precision. These devices facilitate smooth fluid control, making them critical in various applications. Recent market research indicates a steady growth rate of over 6% in the global electric valve market from 2021 to 2026.

Electric Ball Valves offer enhanced automation and integration capabilities, attracting manufacturers aiming for smarter operations. Data shows that companies adopting electric valves can cut energy consumption by 20-30%. However, challenges remain. Users often encounter complexities in initial setup and maintenance, leading to operational hesitations. Industry experts stress the importance of proper training to maximize their potential.

As we explore the top Electric Ball Valves of 2026, understanding their specifications and application suitability becomes vital. This knowledge empowers decision-makers to navigate the evolving landscape effectively. The focus on technology-based solutions signifies a turning point in fluid control systems.

Overview of Electric Ball Valves and Their Functionality

Electric ball valves have become increasingly popular due to their efficiency and reliability. These valves utilize electric actuators to control their opening and closing. The primary advantage lies in their ability to provide precise flow control. According to a recent industry report, the market for electric ball valves is expected to grow at a CAGR of 7.8% from 2021 to 2026. This growth reflects a rising demand in sectors such as water treatment, oil and gas, and chemical processing.

The functionality of electric ball valves is often highlighted by their speed and automation capabilities. They can operate under various conditions, making them suitable for many applications. However, not all electric ball valves perform to expectations. Some users report issues like actuator malfunction or valve seat leakage. These problems can lead to system inefficiencies and downtime. It's crucial for users to choose the right specifications and follow installation guidelines closely. Responses from industry professionals indicate that training and maintenance are critical factors in maximizing valve performance.

Cost is another essential consideration. While electric ball valves may have higher upfront costs, their long-term savings are notable. Reduced maintenance and increased automation lead to lower operating costs over time. However, some facilities may struggle to justify this initial investment. Balancing upfront costs with long-term efficiency remains a common challenge for decision-makers in the industry.

2026 Electric Ball Valves Market Overview

This chart displays the market demand for electric ball valves across different application areas in 2026. Each category represents the estimated units demanded, highlighting key sectors such as residential, commercial, industrial, and agricultural usage.

Key Features to Consider in Top Electric Ball Valves

When looking for top electric ball valves, several key features stand out. One crucial aspect is the actuator type. Different actuators provide varying speeds and power consumption levels. Choosing the right one can affect efficiency significantly. Additionally, consider the valve size. Make sure it matches your pipeline specifications to avoid flow issues.

Compatibility is another essential factor. Ensure that the ball valve integrates well with existing systems. This can prevent potential leaks and minimize maintenance costs. Look at the materials as well. Corrosion-resistant materials can extend the lifespan of the valve, especially in harsh environments.

Tip: Check for adjustable settings. Some electric ball valves allow customization, improving control and flexibility.

Also, pay attention to the control options. Manual overrides can be lifesavers during power failures. They might not be the most advanced feature, but they provide security. Don't overlook noise levels, either. Some electric valves operate quieter than others. This can be beneficial in noise-sensitive environments.

Tip: Always review user feedback. It can provide insights into long-term performance and reliability.

Applications and Industries Utilizing Electric Ball Valves

Electric ball valves play a crucial role in various industries. These devices control the flow of liquids and gases. They are highly efficient and precise. Common applications include water treatment, oil and gas, and HVAC systems.

In the water treatment industry, electric ball valves help manage flow rates. For instance, reports suggest that automation can improve efficiency by up to 30%.

In the oil and gas sector, these valves ensure safety and reliability. Data shows that more than 50% of companies are adopting electric solutions for their operations. This shift reduces human error, a significant concern in hazardous environments. However, not all installations yield immediate benefits. Some systems require extensive tuning and maintenance, which can be resource-intensive.

HVAC systems are another key area. Electric ball valves regulate temperature and airflow. They reduce energy consumption significantly. A recent study indicated that precision control can decrease energy costs by about 15%. Yet, the complexity of these systems can lead to challenges during implementation. Training staff is often necessary to fully leverage the technology.

Leading Brands and Models of Electric Ball Valves in 2026

As the demand for efficient automation grows, electric ball valves are becoming increasingly popular in various industries. In 2026, several leading brands and models will stand out. They focus on reliability, ease of installation, and energy efficiency. These features are vital for reducing operational costs and enhancing productivity in both industrial and commercial applications.

When exploring the various models, users will find that some offer advanced control features. For example, smart connectivity allows remote monitoring and adjustments. This can be a game-changer for facilities needing real-time data. However, it's essential to consider the initial investment. While many options claim to be cost-effective, the long-term benefits must justify the upfront cost.

Users may also face challenges in compatibility with existing systems. Certain models might require additional components for seamless integration. It's important not to overlook these details. The balance between innovation and practicality can be tricky. Improper decisions can lead to inefficiencies, causing frustration for users in the long run. Therefore, thorough research and careful consideration are vital for selecting the right electric ball valve for specific needs.

Maintenance Tips for Optimal Performance of Electric Ball Valves

Electric ball valves are vital in many industries. Proper maintenance ensures their longevity and efficiency. Regular checks are essential for identifying wear and tear. Inspect seals and gaskets for leaks or damage. Replace worn-out parts promptly to avoid larger issues.

Cleaning is another critical aspect. Dust and debris can accumulate over time. Use a soft cloth for the outer surfaces. For the internal components, follow the manufacturer’s cleaning guidelines. Neglecting this step can lead to blockages or malfunctions.

Lubrication should not be overlooked. Greasing joints and moving parts helps in smooth operation. Yet, too much grease can attract dirt. Find a balance for optimal performance. Monitor the valve's performance regularly. Unusual noises or difficulties in operation are signs for immediate inspection.